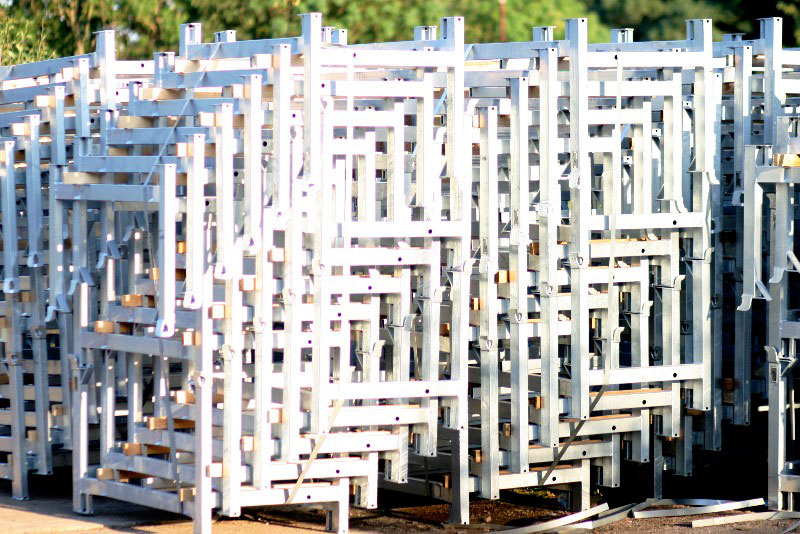

We implement projects in such main industries like: construction, railroading, pressure equipment, machine and automotive.

We work in accordance with our In-Company Production Check-up System based on the grounds of EN 1090-1 standard for the construction class of EXC 4 in the scope of the process of welding, fixing and anti-corrosion protection. Moreover, we work with a certified system of EN ISO 3834-2 that is linked with meeting all the full requirements for the quality of welding process.

In case of railroading, we have been granted a certificate in accordance with the EN 15085-2 standard for the CL-1 level, thanks to which we are able to deal with projects based on the most reliable rail vehicles` components.

What is more, we rely on qualified technologies for welding in accordance with EN ISO 15614-1 for 1.1, 1.2, 8.1 groups of steel, which is certified by WPQR also meeting the requirements of the Pressure Equipment Directive 2014/68/UE. Our welding supervision team members possess the International Welding Engineer (IWE) diploma, whereas the non-destructive testing personnel`s qualifications are in accordance with EN ISO 9712 in the scope of VT, PT, MT, UT testing.